Other products

We apply our creative power developed through solving auto parts manufacturing issues to create further value.

Since our founding more than 60 years ago, we at FUKOKU have been able to solve many problems in a wide range of fields, starting with auto parts manufacturing. Our experience has given us a flexible sense of creativity, which we will use to create new value in a wide range of fields, based on our motto, “Starting with rubber, brightening the future.”

Urethane products

Our products have the top global share in the market due to our original compounding ingredients and superior cast molding and processing technologies.

There are many types of polyurethane used widely in many fields, such as foams, fibers, coatings, adhesives, and elastomers (with thermoplastic and thermosetting properties). We specialize in a type of high-strength thermoset elastomer commonly called cast urethane.

Cast urethane offers better mechanical strength, anti-abrasion performance, and anti-shock performance than synthetic rubber, resin, or any other elastic material, and is therefore used in comparatively severe (high-load, high-speed, or high-impact) environments.

FUKOKU focuses on abrasion resistance performance—the greatest benefit offered by cast urethane—and continues to go beyond industry conventions to develop materials with even greater abrasion resistance performance.

We leveraged the material technologies, molding/processing technologies, and quality management system we have developed for automobile-related parts in winning a top global share in wire saw equipment (used to cut ingots)—particularly in urethane rollers for semiconductor wafers.

Example urethane products

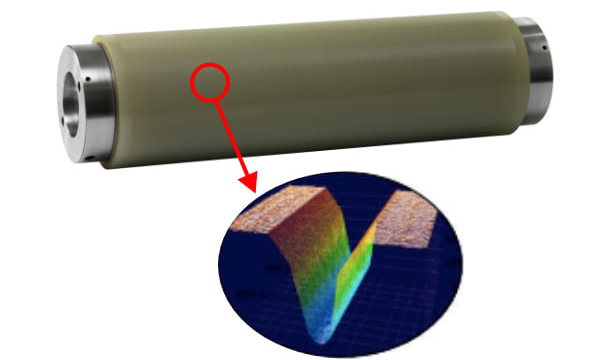

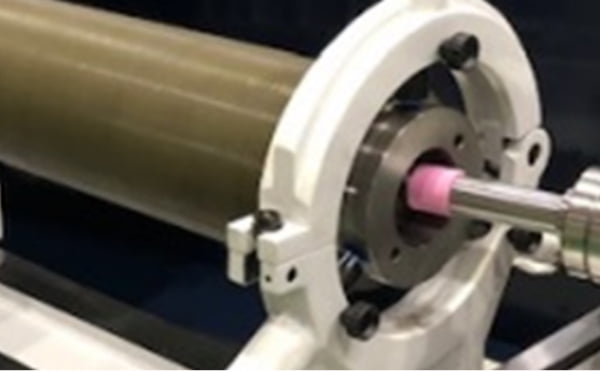

Main rollers for ingot wire saws

We provide integrated production in-house that covers all processes, from material design to molding and shipping. Our maintenance processes (such as core inner diameter shaving) result in a high runout accuracy, allowing us to maintain a high level of quality while supplying products with optimal lead times.

Manufacturing processes

Material selection > Core maintenance > Pre-treatment > Urethane molding > Post-processing > Measurement/inspection > Shipping

Urethane pulleys

We manufacture wire saw rollers, guide rollers, and all types of urethane pulleys.

Our original mixture design allows us to manufacture special urethane with increased abrasion and liquid resistance properties, and our products have been evaluated on actual machines, demonstrating a longevity three to five times normal.

We offer a full lineup of products including water-resistant and oil-resistant grade products to meet your application.

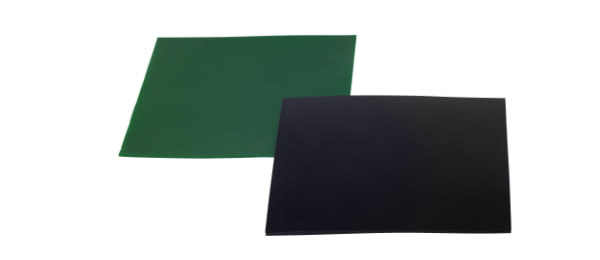

Octron mats

These urethane mats deliver stable electrostatic diffusion properties.

They can eliminate problems caused by electrostatic charging and electrostatic discharging. Made from urethane, they provide superior durability and include no carbon-based filler, and can therefore be used even in cleanroom environments. They are ideal for use on workspace floors or workbenches, or as antistatic pads.

They are also electrostatic throughout their thickness direction , so surface abrasion or wiping and cleaning will not cause performance degradation.

Volume resistance: 10⁷ to 10⁸Ω (JIS K6911)

Why people choose FUKOKU’s urethane products

01Our integrated production system provides customers with total solutions

(Main rollers for ingot wire saws)

Integrated production for high quality and short lead times

All processes are handled in-house through integrated production, allowing us to ensure a high level of quality while minimizing lead times.

Thorough maintenance to improve precision and durability

FUKOKU performs maintenance on your roller cores.

Our maintenance can increase runout accuracy during rotation, help maintain precision in processed products, and improve equipment durability. The services have won high acclaim from our customers.

Original devices provide highly stable operation during production

We use original elastomer casting machinery when mixing and stirring materials, resulting in accurate and stable physical properties.

02Foundational rubber technology and quality management developed in the automotive industry

Material technologies

FUKOKU is a specialist manufacturer of synthetic rubber for various industries.

We have more than 1,000 different compounds and leverage our experience and knowledge in urethane material mixture technologies.

Product evaluation technology

We use various kinds of analytical equipment to analyze organic compounds (including testing equipment such as universal material testers, friction/abrasion testers, and single wire saw evaluators) to provide reliable quality management.

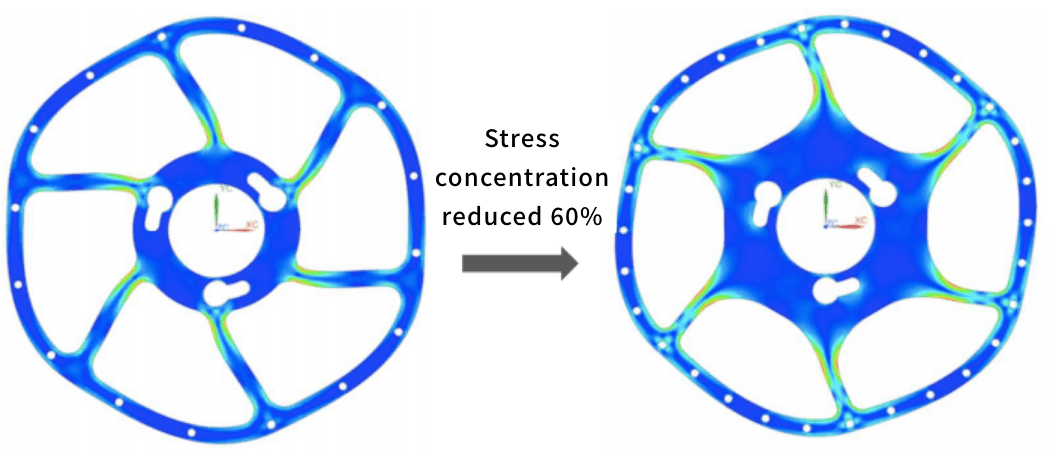

Analysis/design technology

We use tests such as stress simulations based on our original FEM analysis technology to design optimal products and save wasted resources.

Example stress analysis simulation: Wire saw guide roller core

Example of using FEM analysis to propose shape to reduce stress concentration

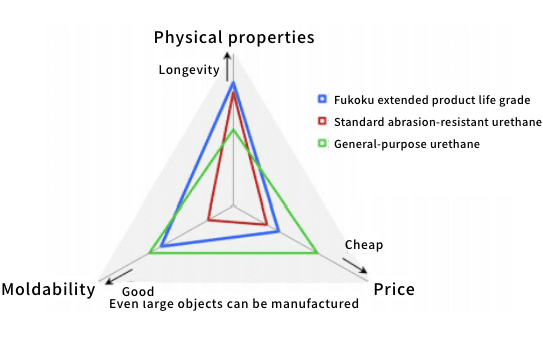

03FUKOKU uses a wide variety of urethane materials, allowing customers to choose them that best suits their usage environment and conditions

FUKOKU original long life grade

- This special urethane offers increased abrasion and liquid resistance properties based on our original mixture design. Evaluations on actual machines have demonstrated a longevity three to five times normal.

- Our original and innovative mixing technology allows us to form large products that could not be formed from standard abrasion-resistant urethane material.

- We also offer water-resistant and oil-resistant grade products. This allows customers to select the product that is best suited for their application.

- Our urethane products retain their physical properties, shape, and processing accuracy from starting of the usage to the end of life, resulting in better quality, stable production, and a longer product life—which means reduced costs for customers.

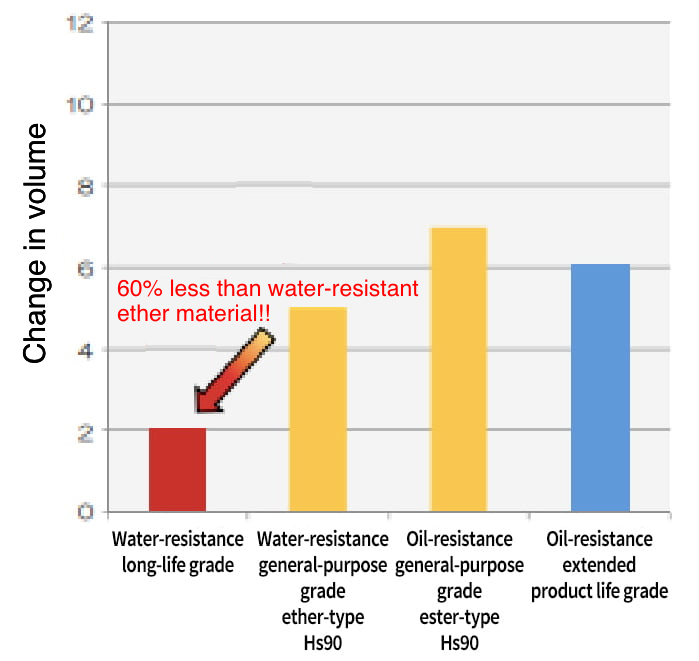

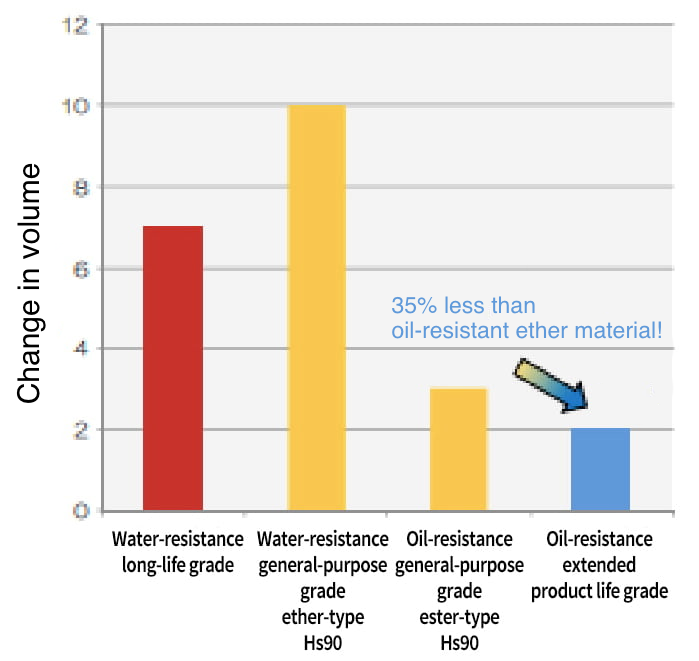

Physical properties comparison with long-life grade

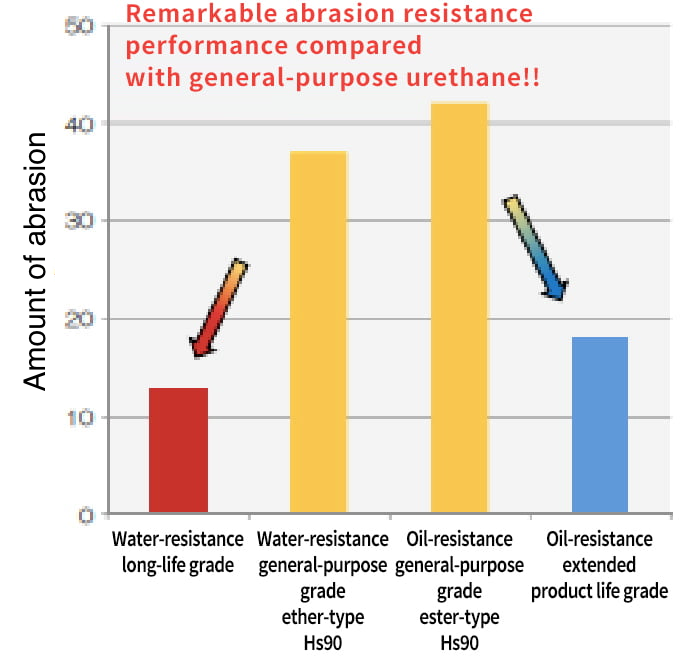

Anti-abrasion performance

Water-resistance coolant performance

Oil-resistance coolant performance

Representative mixture:

Physical properties

| Item | Unit | General-purpose grade | Extended product life grade | ||||

|---|---|---|---|---|---|---|---|

| Ether-type Hs90 |

Ether-type Hs95 |

Ester-type Hs90 |

Ester-type Hs95 |

Water-resistance Hs92 |

Oil-resistance Hs92 |

||

| Hardness | Durometer TYPE A |

90 | 95 | 90 | 95 | 92 | 92 |

| Tensile strength | MPa | 40 | 50 | 52 | 53 | 42 | 40 |

| Stretching | % | 410 | 350 | 400 | 440 | 600 | 700 |

| 100% tensile stress | MPa | 9 | 13 | 8 | 12 | 9 | 8 |

| Tensile strength | kN/m | 93 | 108 | 87 | 107 | 110 | 122 |

| Taber abrasion Abrading wheel: H-22, weight: 1 kg No. of rotations: 1,000 |

mg | 37 | 40 | 42 | 57 | 13 | 18 |

Contact us about urethane products

Contact us

Please submit any inquiries here.

Find! FUKOKU in Industrial Machinery

We continue to develop technologies and products that help bring industrial machinery to the next level.

Contact us

Please submit any inquiries about products or recruiting using the respective inquiry forms.